How do manufacturers distress jeans?

How do manufacturers distress jeans?

summary

Distressed jeans, characterized by their worn and vintage appearance, have become a significant trend in the fashion industry, blending aesthetics with a sense of individuality. The process of manufacturing these garments involves a series of specialized techniques designed to create the desired distressed effects while maintaining the jeans' durability. This has garnered attention due to the environmental implications of traditional manufacturing methods, which often involve extensive water use, chemical treatments, and other practices that contribute to pollution and resource depletion.

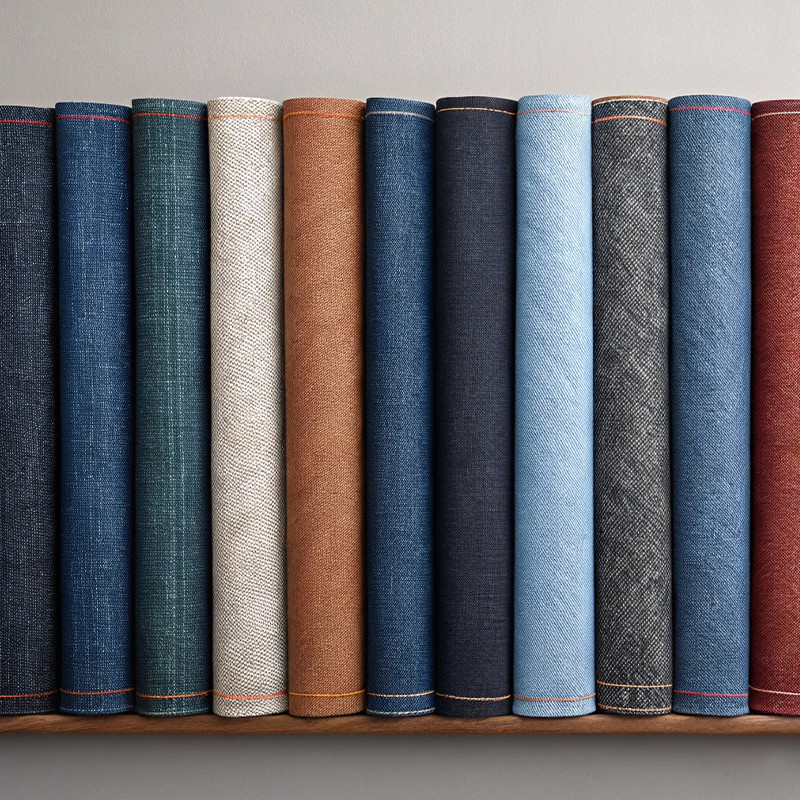

The distressing process includes various methods such as fraying, tearing, bleaching, acid washing, and sanding, each contributing to the unique look and texture of the jeans.

While these techniques enable manufacturers to produce distinctive products, they also raise significant environmental concerns. For example, the traditional denim manufacturing process can consume over 790 gallons of water for a single pair of jeans, highlighting the industry's unsustainable practices and prompting a search for more eco-friendly alternatives.

As a response, many brands are increasingly adopting sustainable materials and innovative technologies, such as laser washing and ozone treatment, which reduce chemical and water usage significantly.

Despite the notable popularity of distressed jeans, the manufacturing process is not without controversy. The industry faces criticism for its ecological footprint and the health risks posed to workers due to exposure to harmful chemicals.

In light of rising consumer awareness and demand for sustainable practices, many companies are reevaluating their production methods, seeking ways to mitigate environmental impact while delivering high-quality, fashionable products.

Overall, the combination of style, sustainability, and ethical concerns surrounding distressed jeans highlights an evolving landscape in the denim industry, as brands navigate consumer expectations and regulatory pressures while striving for a more responsible approach to fashion production.

Manufacturing Process

The manufacturing process of distressed jeans involves a series of meticulous steps aimed at achieving the desired aesthetic while ensuring the durability of the final product. This process is an intricate blend of traditional techniques and modern technology.

Pre-Production

Pattern Making and Fabric Inspection

Before the distressing techniques can be applied, a solid foundation is laid during the pre-production phase. This begins with the careful cutting of denim fabric according to precisely designed patterns. The pattern is used as a guide to ensure that the fabric pieces are cut into the correct shapes and sizes

. Prior to cutting, fabric inspection is crucial to identify any defects, ensuring only high-quality materials are used. Additionally, grain lines are meticulously aligned with the fabric's weave to maintain structural integrity

Sewing and Fitting

After cutting, the pieces are sewn together with skill and precision. This alignment is critical to achieving a neat finish and ensuring that the jeans fit well. Once assembled, the jeans are fitted on a model or mannequin for adjustments, which are made to ensure an optimal fit

Distressing Techniques

Overview of Distressing

Distressing is a technique employed to create a worn, vintage look on jeans. It involves manipulating the fabric to create fades, small tears, and frayed edges, adding character and uniqueness to each pair.

. Understanding the types of fibers and treatments applied to the fabric is essential for achieving desirable results.

Common Methods

Fraying and Tearing

This involves deliberately damaging the fabric by pulling out threads along the edges or ripping the fabric at strategic locations. These methods enhance the texture and ruggedness of the jeans

Bleaching

Bleaching is used to create faded and discolored areas on the fabric, mimicking natural wear over time. This technique adds to the overall distressed aesthetic

Acid Washing

A more advanced distressing method involves applying acid or bleach in a controlled manner to create mottled and uneven patterns, resulting in unique textures that make each piece distinctive

Sanding and Abrasion

Using tools like sandpaper or Dremel tools, manufacturers can create a softer feel and worn appearance on certain areas of the jeans. This method requires precision to ensure uniformity across batches, especially when teaching large teams how to replicate the techniques consistently

Technological Advancements

The integration of technology has revolutionized the distressing process. Computerized cutting systems and robotic laundry machines enable manufacturers to achieve intricate designs while minimizing material waste. Innovations such as ozone washing allow for eco-friendly bleaching methods that drastically reduce water and chemical usage, enhancing both sustainability and efficiency.

Final Production Stage

Following distressing, the jeans move into the production stage where mass production takes place. This final phase encompasses refining the distressed effects and preparing the jeans for market, ensuring that every pair meets the high standards of craftsmanship expected by consumers

Materials Used

The choice of materials plays a pivotal role in the production of distressed jeans, impacting both the garment's sustainability and performance.

Sustainable Fabrics

Many manufacturers are increasingly opting for sustainable fabrics such as recycled cotton, organic cotton, and hemp to create their denim products. These materials are chosen for their minimal environmental impact, contributing to a more sustainable fashion industry.

In addition to these natural fibers, eco-made elastane and ROICA™, which are degradable and produced with fewer harmful chemicals than conventional elastane, are used to provide stretch in products like jeans

Innovative Denim Technologies

To further enhance sustainability, brands are adopting advanced technologies in their denim production. For instance, laser washing techniques not only reduce water waste but also increase energy efficiency during the finishing process.

Additionally, the use of Jeanologia’s Environmental Impact Measuring tool allows manufacturers to monitor the ecological footprint of their garments and optimize their processes accordingly

Eco-Friendly Components

Apart from the main fabric, the components of jeans also reflect a commitment to sustainability. Manufacturers are increasingly sourcing compostable packaging and labels made from organic cotton or recycled polyester, and they ensure that swing tags have an FSC certification, promoting responsible forest management.[8]

Moreover, natural rubber is being sourced instead of conventional petroleum-based plastics, making denim garments microplastic-free and biodegradable within two years.

Recycling and Waste Minimization

To minimize textile waste, many companies implement limited production runs and recycling initiatives, such as Circle Back Programs, encouraging consumers to return their used garments for recycling.

Recycled denim, created from shredding previously worn jeans, is also becoming popular as it significantly reduces resource consumption and waste, aligning with growing environmental concerns.

Environmental Concerns

The process of manufacturing denim, particularly through distressing techniques, raises significant environmental concerns. The denim industry has been scrutinized for its substantial ecological footprint, which includes excessive water consumption, chemical use, and pollution throughout the production cycle. A single pair of jeans can require over 790 gallons of water from cotton cultivation to final washing, highlighting the industry's high water dependency and potential for depleting local water sources

. Furthermore, traditional dyeing methods often utilize carcinogenic chemicals that contaminate waterways, posing serious health risks to nearby communities

. The distressing process itself also contributes to environmental degradation. Various techniques, such as sandpapering and bleaching, generate waste and require the use of chemicals that can be harmful to both the environment and workers' health. Although some companies are innovating to reduce their ecological impact—such as using engineered enzymes for dyeing that cut environmental impacts by up to 92 percent compared to conventional methods

—the industry still faces ongoing challenges in fully mitigating its environmental footprint. In response to rising public concern about climate change and pollution, many denim manufacturers are exploring sustainable practices that minimize water and chemical usage. These changes are not only beneficial for the environment but also reduce operational costs, making sustainable practices appealing for businesses

. However, the shift toward more eco-friendly methods is still in its infancy, and the industry continues to grapple with how best to implement these changes while maintaining product quality and consumer demand. As awareness grows about the environmental consequences of denim production, the industry is under increasing pressure to adopt more responsible manufacturing practices. This includes finding alternatives to harmful dyes and reducing water consumption in distressing techniques, ultimately aiming to create a more sustainable future for denim fashion

Market and Consumer Trends

he denim market has seen significant evolution over the years, adapting to shifts in consumer behavior and broader economic conditions. In the United States, the denim jeans market was valued at approximately $15.8 billion in 2022, with predictions for growth in other regions such as China, which is expected to reach $21.3 billion by 2030, growing at a compound annual growth rate (CAGR) of 7.2% during the analysis period from 2022 to 2030

. Emerging markets, particularly in Brazil and China, represent key areas for expansion, allowing brands to penetrate lower-profit segments such as women's tops

. As brands adapt to the values of a more conscious shopper, particularly among the Gen Z demographic, the retail experience has become increasingly important. This generation prioritizes integrity and sustainability in their purchasing decisions, often seeking out brands that align with their values

. Companies like Levi's have recognized this shift and are investing in enhancing the retail experience in flagship stores globally, encouraging customers to shop in-person rather than online. They aim to build a connection with consumers by taking a stand on important social issues, which resonates with the activist mentality of Gen Z

. The sustainability crisis in the fashion industry, exacerbated by the production and distribution of clothing, overconsumption, and trend culture, has prompted brands to seek innovative solutions. Levi's, for instance, is increasingly focused on its environmental impact, particularly concerning the significant resources required to produce denim—averaging 10,000 liters of water for a single pair of jeans

. The company's initiatives have included adopting new technologies, such as laser technology for distressing jeans, which has seen 15-20% of its products incorporate this innovative approach to reduce waste

. As the market evolves, AI and body scanning technologies are paving the way for bespoke denim experiences. These advancements allow for the creation of better-fitting jeans tailored to individual body shapes, thus minimizing returns and waste associated with poor fits

. This trend aligns with the increasing demand for direct-to-consumer retail, where personalization is key in capturing the interest of today's consumers

Purchase custom multi-pocket patchwork jeans by DiZNEW. Unique distressed denim with utility pockets, tailored for high-fashion streetwear.

Men's distressed patchwork denim jeans with rugged rips and frayed details, offering a bold vintage style for streetwear and casual looks.

Premium quilted cargo denim featuring delicate botanical prints and innovative string details. Custom light wash with artistic pattern design.

Discover Men's Custom Waxed Denim Jeans | Premium Coated Finish | Perfect for brands seeking OEM, ODM, and wholesale solutions. Style that stands out!